Over the past few decades, craft breweries have expanded rapidly across the USA & Canada, with many located in rural and destination settings. While the location can be ideal from a market perspective, the lack of infrastructure can present real challenges for the brewery tasked with providing all major utility services (e.g., Power, Water and Wastewater). When dealing with Wastewater, a brewery can consider several solutions, each with their own unique challenges.

Great location. Now where does all the wastewater go?

Know when to hold it, know when to treat it:

1. Holding & Hauling

This strategy involves a low initial CAPEX but the OPEX of hauling in an industry that has a >5:1 ratio of water to product can become cost-prohibitive quickly. In addition, with many municipalities dealing with aging infrastructure, the number of sites that will accept offsite wastewater are shrinking while tariffs are growing.

2. Connect to local sewer network

This is, by far, the simplest solution from a daily operations perspective. Many municipalities only require a brewery to achieve simple pH targets (5-9) and BOD (BioChemical Oxygen Demand) limits that can be achieved with simple source separation of high organic-load streams (e.g., side streaming spent yeast, etc.). The main challenge from this approach is cost and planning. Most sewer connection charges can exceed the full brewery build out cost and take years to approve and complete.

3. Onsite wastewater treatment

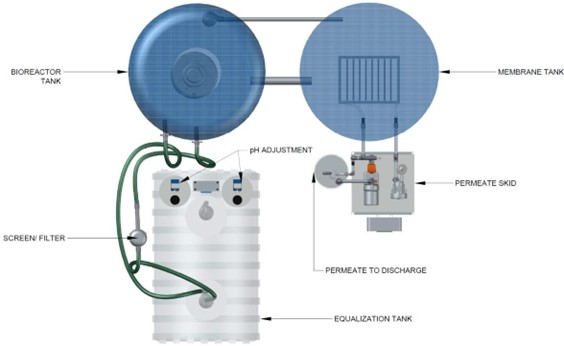

A third option for rural breweries is to treat their effluent onsite to a level that can safely be discharged to the environment or reused onsite. While the perceived complexity is high, the principles of treating high strength organic wastewater are well developed and have been deployed for decades in many other industries.

The Good the Bad and the Bacteria

When de-mystifying the principles of onsite wastewater treatment, the first point to remember is that all biological wastewater treatment is based on the use of beneficial bacteria to digest the organic material in the stream. Much like the brewing process which uses bacteria to transform ingredients into product, wastewater treatment uses bacteria to convert the high carbon loads of the wastewater into gases and H2O. By far the most common technology for treatment of low flow high strength wastewater, such as what is found in Craft Breweries, is aerobic digestion. With a better than 100-year track record, the aerobic digestion process is the work horse of both municipal and industrial wastewater treatment.

The principles of Aerobic Treatment can be broken down into three basic steps:

When selecting a treatment strategy for your rural brewery wastewater, it is important to consider the CAPEX and OPEX implications of any approach. While hauling might appear to be a viable approach to delay CAPEX, the tightening regulations and increasing tariffs related to this strategy mean that you will want to design your brewery so that you can either shift to onsite treatment or sewer connection if required. Onsite treatment has the advantages of being able to control and contain the OPEX related to brewhouse effluents and also the possibilities to tap into opportunities for onsite reuse. However, any treatment strategy needs to be combined with an operations strategy both at the front (brewhouse) and end (wastewater system) of the process to achieve your treatment objectives.